Newly Formed Bison® Combines

AMETEK Dynamic Fluid Solutions and

Bison Gear and Engineering Corp.

Offering Customers. . .

-

An Expanded Product Portfolio

-

Unparalleled Design Expertise, Customizable Solutions and Integration Support Serving Many Markets

-

Accelerated Time to Production

- Global Insights and Worldwide Manufacturing Flexibility

Parallel Shaft Gearmotors

-

Parallel Shaft

Parallel Shaft

010 SeriesGearmotors -

Parallel Shaft

020 Series

Gearmotors

-

Parallel Shaft

o30 Series

Gearmotors

-

Parallel Shaft

040 Series

Gearmotors

-

Parallel Shaft

050 Series

Gearmotors

-

Parallel Shaft

100 Series

Gearmotors

-

Parallel Shaft

175 Series

Gearmotors

-

Parallel Shaft

200 Series

Gearmotors

-

Parallel Shaft

261 Series Sanimotor

IP69K Washdown Gearmotors

-

Parallel Shaft

300 Series

Gearmotors

-

Parallel Shaft

400 Series

Gearmotors

-

Parallel Shaft

483 Series

Gearmotors

-

Parallel Shaft

650 Series

Gearmotors

-

Offset Parallel Shaft

562 Series

Gearmotors

-

Offset Parallel Shaft

762 Series

Gearmotors

Right Angle Gearmotors

-

Right Angle

Right Angle

060 SeriesGearmotors -

Right Angle Hypoid Gearing

712 Series PowerSTAR

Gearmotors

-

Right Angle Hypoid Gearing

Right Angle Hypoid Gearing

720 Series PowerSTAR

Gearmotors -

Right Angle Hypoid

Right Angle Hypoid

725 Series PowerSTAR

Gearmotors -

Right Angle Hypoid

730 Series PowerSTAR

Gearmotors

-

Right Angle

Right Angle

746 Series

Gearmotors -

Right Angle

750 Series

Gearmotor

Motors

-

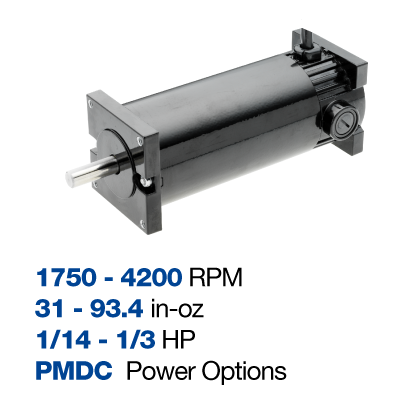

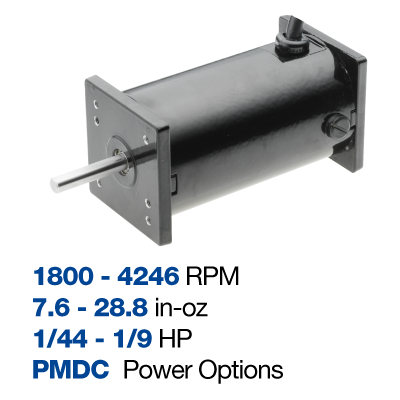

PMDC

PMDC

203 SeriesMotors -

PMDC

206 Series

Motors

-

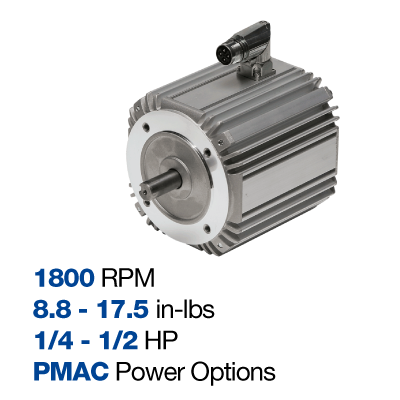

IEC71 Series VFsync

PMAC Motors

-

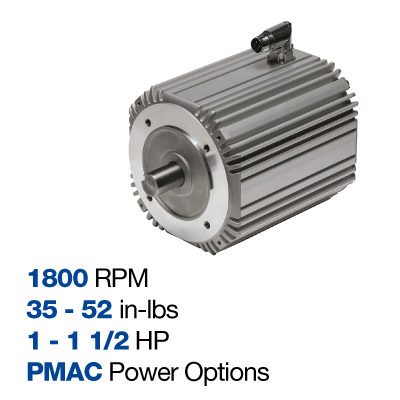

IEC80 VFsync

IEC80 VFsync

PMAC Motors

-

IEC90 VFsync

PMAC Motors

-

NEMA56C Series VFsync

NEMA56C Series VFsync

PMAC Motors

-

SS30 Stainless Steel

IP69K Washdown Motors

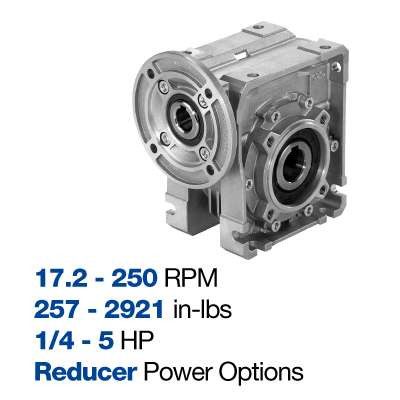

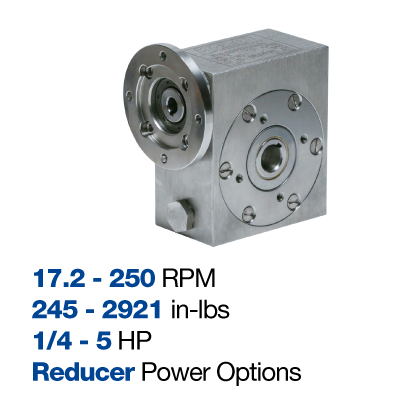

Gear Reducers

Contact Bison

UNPARALLELED. . .

Design Expertise

Customizable Solutions

Integration Support

. . .SERVING MANY MARKETS

-

Ag &

Ag &

Construction -

Energy

Energy -

Food &

Food &

Beverage -

IndustrialMachinery

IndustrialMachinery -

MotionControl

MotionControl -

Transportation

Transportation

ACCELERATED TIME TO PRODUCTION

With state-of-the-art-engineering laboratories in Kent, OH; Shanghai, China; and St. Charles, IL, Bison® is even more equipped to help customers accelerate time to production.

GLOBAL INSIGHTS AND WORLDWIDE MANUFACTURING FLEXIBILITY

-

Worldwide Research Facilities

-

International Sales Representation

-

Manufacturing Flexibility

Bison® -- the newly created AMETEK business -- manufactures products at AMETEK facilities in Whitsett, NC and St. Charles, IL

in the United States as well as in Reynosa, Mexico and Shanghai, China.

About Bison®

For more than 100 years, Bison® has helped customers differentiate their products by developing robust, flexible and durable motors, blowers and pumps under the brand names – Bison® Gearmotors, Lamb®, Nautilair®, Prestolite Motors, ROTRON® Regenerative Blowers, ROTRON® Transportation and Windjammer®.

Bison® engineers thrive on technical challenges and provide customers collaborative, customizable and optimized fluid-moving, fractional and integral horsepower solutions. Bison® has worldwide sales representative support, research facilities and manufacturing facilities in the United States, China and Mexico. The company is headquartered in Kent, Ohio.

Bison® is a business of AMETEK, Inc. -- a leading global provider of industrial technology solutions serving a diverse set of attractive niche markets with annual sales over $6.0 billion.